ADL Cryogenic Oxygen Plant

COMPARISON BETWEEN MEDICAL OXYGEN PRODUCED FROM CRYOGENIC PLANT VS PSA OXYGEN GENERATOR

| QUESTIONS AND FAQ | OXYGEN PRODUCED FROM CRYOGENIC OXYGEN PLANT RECOMENDED | OXYGEN PRODUCED FROM PSA OXYGEN GENERATORS NOT RECOMENDED |

|---|---|---|

| QUALITY OF OXYGEN REQUIRED FOR HOSPITAL/MEDICAL | OXYGEN PURITY 99% TO 99.5% is Essential | OXYGEN PURITY 93-95% IS LOW & after few months of operation it comes down to 85-90%. |

| WHAT ARE HYDROCARBONS & CARBON MONOXIDE LEVELS | OK SEE TABLE GIVEN BELOW | High levels of hydrocarbons & Carbon monoxide. IS LIKE POISON & THE PATIENT CAN GO INTO COMA |

| DOES THE OXYGEN QUALITY PASS AMERICAN/EUROPEAN/ INDIAN/JAPANESE PHARMACOPEA? | YES | NO CANNOT QUALIFY PRACTICALLY IN A FEW WEEKS/MONTHS OXYGEN PURITY FALLS TO A UNSAFE LEVEL BELOW 82% (WHO) MAY CAUSE BRAIN/LUNG DAMAGE |

| WHAT IS THE SAFE WAY TO FILL MEDICAL OXYGEN CYLINDERS AT 150 BAR/2200 PSI? | BY AN OIL FREE LIQUID OXYGEN PUMP ONLY AND NEVER BY OXYGEN COMPRESSOR | PSA PLANT CAN FILL OXYGEN IN CYLINDERS ONLY BY OLD TYPE OF OXYGEN COMPRESSOR. HIGH RISK OF CONTAMINATION + H20+CO +VIRUS/BACTERIA SO IS NOT SAFE (ALSO COMPRESSION CAUSES EXPLOSIONS / SEE CIRCULAR) |

| WHERE PSA PLANTS ARE USED? | USED FOR MEDICAL HOSPITAL/EMERGENCY/OT/ICU | PSA PLANT WAS USED 30 YEARS AGO DUE TO UNAVAILABILITY OF SMALL CAPACITY COMPACT CRYOGENIC OXYGEN PLANTS. |

| WHAT IS THE RELIABILILY? WHAT ARE RISK INVOLVED IN APSA PLANT VS A CRYOGONIC | HIGH RELIABILILY & FAST RETURNS ON THE INVESTMET CRYOGENIC MEDICAL OXYGEN PLANT HAS ZERO RISK | LOW RELIABILILY & LOW RETURNS OXYGENBREATHED FROM APSA OXYGEN PLANT MY DAMAGE THE LANGE/ HEARTH BRAIN OF THE PERSON/ PATIENT DUE TO LOW PURITY & CONANMANTION |

FAQ

A PSA Oxygen plant is an obsolete system consisting of a chemical tower which

adsorbs the nitrogen and carbon dioxide /carbon monoxide /h20 incompletely as a result

gives only 80% to 93% purity theoretically and passes the impurities along with the oxygen .

Practically in a few weeks/months oxygen purity falls to a unsafe level below 82%

(as per who) causing sever harm & damage to the patient.

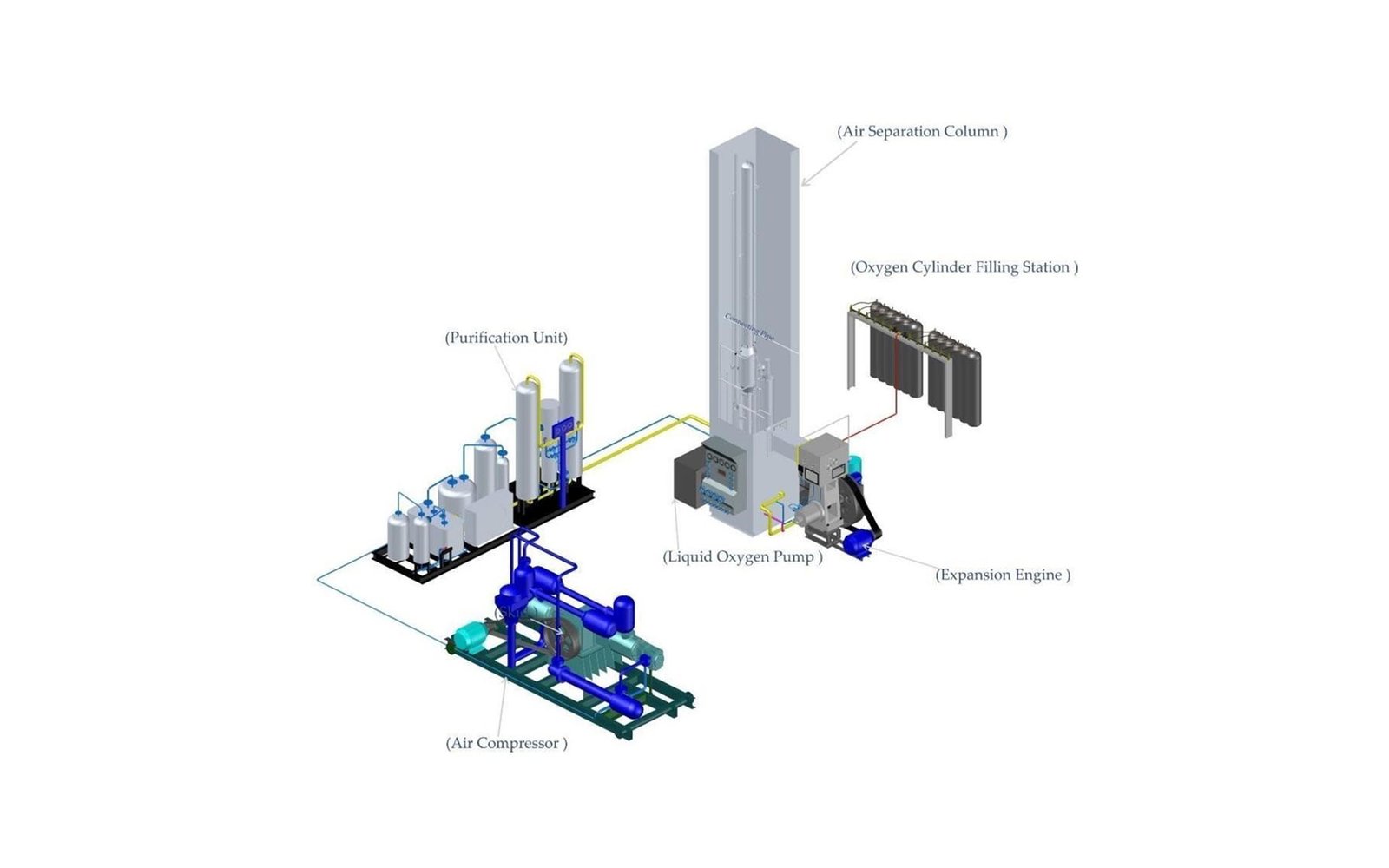

“IT IS BY INSTALLING A CRYOGENIC OXYGEN PLANT/AIR LIQUIFICATION PROCESS ONLY TO PROVIDE RELIABLE MEDICAL

OXYGEN GAS CYLINDER FILLING AND SUPPLYING THE HOSPITALS OXYGEN VIA CYLINDERS”

- Oxygen storage and intra-hospital distribution Oxygen cylinders: Oxygen gas can be compressed and stored in cylinders.

- These cylinders are filled at a gas manufacturing plant, either via a cryogenic distillation and then transported to health facilities.

- Cylinders can be used in one of two ways. One, by installing them directly within patient areas or, similar to direct piping and two, by connecting them to sub-central manifold systems (groups of cylinders linked in parallel) at the facility. Thus, oxygen can be piped to specific areas of the health facility, even at the ward level.

- Once filled, cylinders themselves do not require electricity.

“It is produced by a Purification process followed by the distillation of the liquefied ambient air”

EXPLOSIONS HAVE OCCURRED IN CHEMICAL OXYGEN GENERATORS.

Commercial aircraft provide emergency oxygen to passengers to protect

them from drops in cabin pressure. Chemical oxygen generators are not

used for the cockpit crew, who are typically supplied using Compressed

oxygen canisters also known as oxygen bottles. In narrow body airliners,

for each row of seats there are overhead oxygen masks and oxygen generators.

In some wide-body airliners, such as the DC-10 and IL-96, the canisters and

oxygen masks are mounted in the top portion of the seat backs, since the

ceiling is too high above the passengers. If a decompression occurs, the

panels are opened either by an automatic pressure switch or by a manual switch,

and the masks are released. When the passengers pull down on the mask they

remove the retaining pins and trigger the production of oxygen.